ATC Resources

Interoperability within the ATC Visual System

The ATC Visual System

How to avoid compatibility issues and reduce risk when upgrading an ATC’s visual system.

skeyes, where EIZO solutions are deployed.

skeyes, where EIZO solutions are deployed.

In the ATM industry, systems are designed to suit the physical space and geographical characteristics of each site while considering specific customer requirements. As systems becomes more complex, interoperability becomes a significant concern, risking severe performance issues if device interaction is not seamless. Furthermore, future upgrades and replacements due to end-of-life hardware issues can prove costly each time they are needed. This means initial decisions related to specific technologies have a direct impact on longevity and mission-critical performance of those systems. This article covers common pitfalls in purchasing decisions at the individual product level and emphasizes the importance of considering the entire ATC visual system and future upgrades prior to deployment.

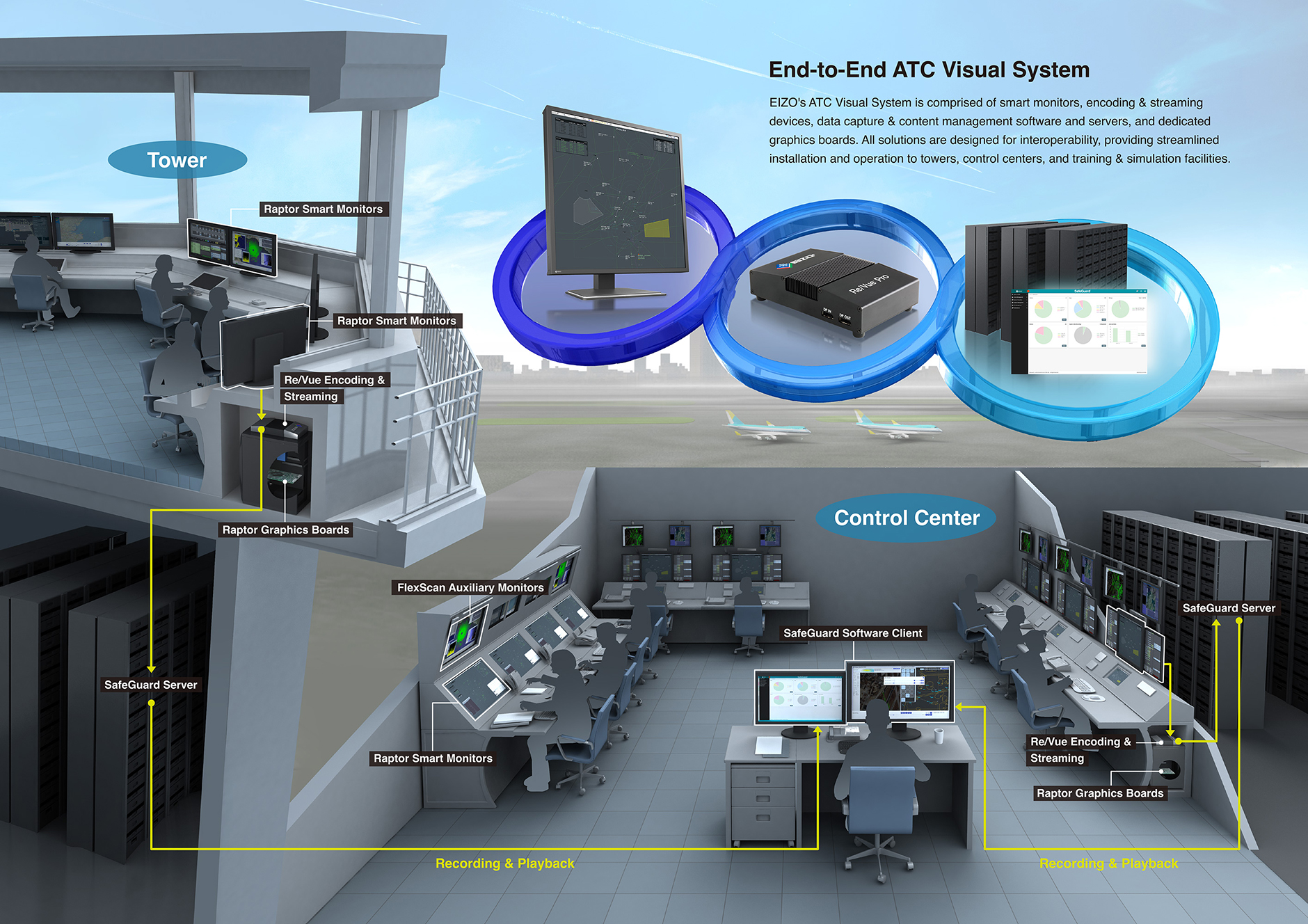

The ATC visual system consists of several graphics-related devices designed to transfer ATM video data and associated control system Graphical User Interfaces (GUI) to the controller. This ‘imaging chain’ consists of a range of hardware devices such as graphics cards, video extenders, KVM switches, video encoders, and associated recording solutions and monitors. These devices must work together seamlessly to ensure the controller is presented with accurate video data, while also recording the data for maintaining a record of communications to aid in the post-incident investigative process, support search-and-rescue operations, and verify and validate connected systems.

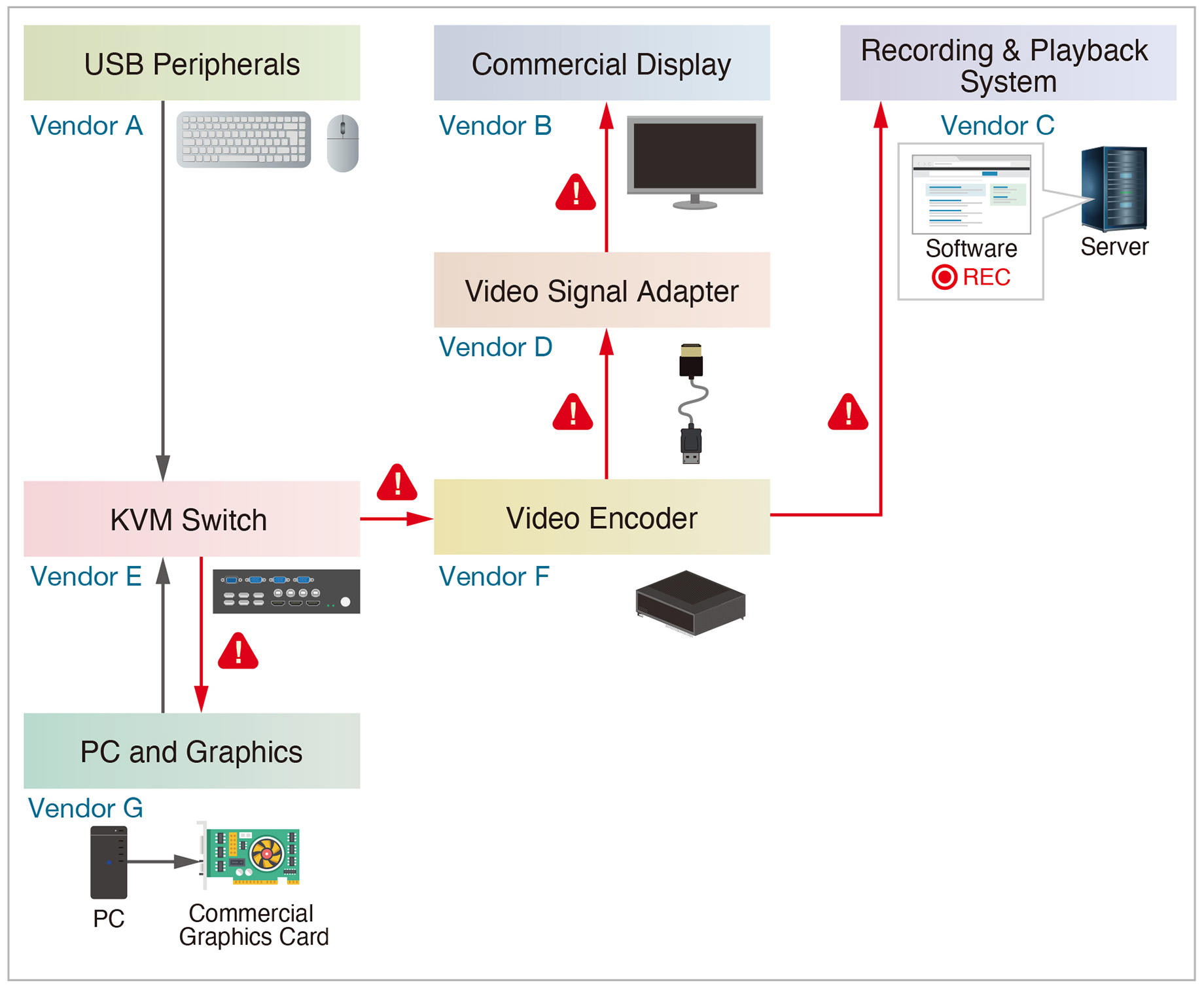

Example of a conventional ATC visual system comprised of hardware and software from multiple vendors and areas at risk for interoperability issues.

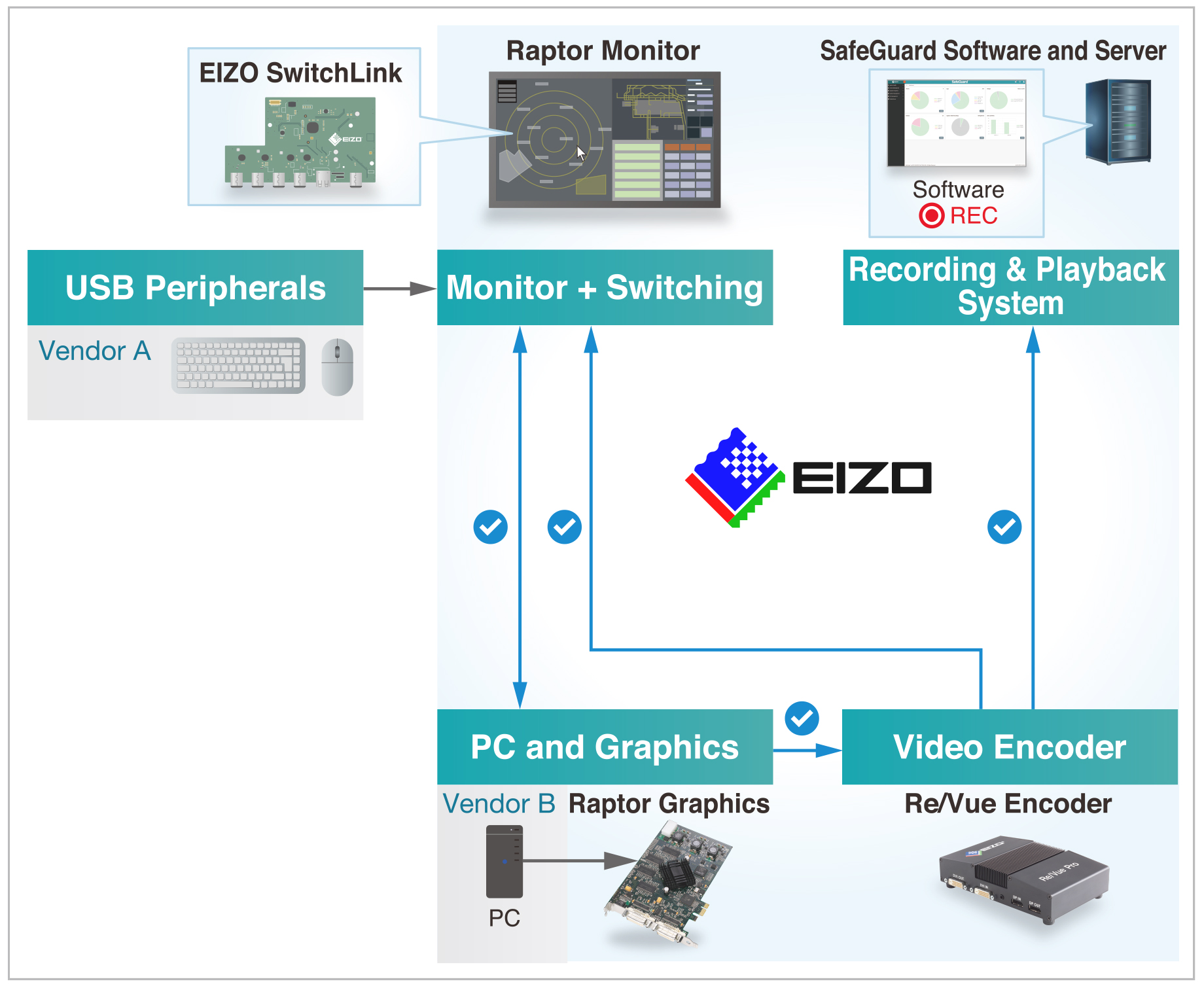

Example of EIZO’s ATC visual system with proven solutions that eliminate interoperability concerns.

Deployed systems are typically either complete integrated solutions procured by a system integrator or have individual sub-systems with a range of solutions that are updated over time. While there is the expectation that newer technology and open standard interfaces should allow all systems to co-exist without issue, the dependencies on adjacent sub-system technologies often result in a design that is so restrictive or specific that future upgrade or replacement decisions are taken out of the ANSP’s hands.

Issues with interoperability and compatibility between various device types can cause numerous technical issues including screen flicker, periodic loss of image, and high data rates from video encoders. These issues may be related to cable quality, graphic card configuration (as most commercially available graphics cards are designed for gaming and other non-mission critical industries), signal support limitations, firmware and OS compatibility, manufacturer tolerances (e.g., timing precision in video transmission), and quality in design and manufacturing.

Challenges in Video Signal Conversion

At the core of the ATC visual system are the components that serve as the ATCO’s center of visual focus – the information displayed on the monitor. In the early 2000s, the market transitioned away from CRT monitors, but early LCD monitors were still driven by analog sources allowing the use of the same ATM-grade graphics boards and cables that were already in place. As visual display technology advanced, there was a mass migration to digital technologies such as DVI and eventually DisplayPort. This led to the emergence of new commercially available devices which were starting to be considered for integration to modern ATC visual systems. However, commercial products are not designed for mission-critical environments, presenting additional new challenges to the market.

A wider range of manufacturers providing display hardware for a modern ATC visual system gave rise to competing video signal interfaces within the imaging chain itself. One such situation common in today’s environment is the combined use of DisplayPort and HDMI-equipped devices. For example, a DisplayPort graphics card and monitor combined with a video switch device that requires conversion to HDMI.

While a video adapter may appear to provide a simple solution, active circuitry is required to convert between these video standards which introduces a new level of complexity.

- DisplayPort and HDMI have different electrical characteristics. DisplayPort outputs are AC-coupled CML (Current Mode Logic) while HDMI uses TMDS (Transition Minimized Differential Signaling). Although some DisplayPort devices do support a dual-mode version that will support TMDS in compatibility mode, this is not a given.

- DisplayPort can provide 3.3v DC power on pin 20 but this feature (DP_PWR) is primarily intended for cable adapters like active extenders and converters. Therefore, standard DisplayPort video cables do not have this pin populated or it is not electrically connected inside the cable. Custom cables with this power feature do exist but should only be used when an intermediary device specifically requires this power feature.

- An active circuit adapter is required to convert the signal type if converting between DisplayPort to HDMI or HDMI to DisplayPort. However, a standard cable in front of the adapter that does not provide power over pin 20 could render the adapter useless since it would not provide the necessary power unless the adapter had an external power supply.

- This type of active circuit adapter is designed to be a one-way converter. A DisplayPort to HDMI adapter must be used at the DisplayPort source receptacle and cannot be used to adapt HDMI to DisplayPort.

Video converters represent an additional point of failure, thus threatening the reliability of the system. Signal conversion may also reduce the quality of the signal which can cause other devices throughout the imaging chain to experience issues.

| EIZO’s Raptor monitors are equipped with multiple video inputs that allow migration from, for example, analog to DVI or DVI to DisplayPort without the need for a monitor change later. In addition, EIZO’s Re/Vue Pro 2 Max video encoder is equipped with DVI-D and DisplayPort interfaces allowing for systems to be updated from a DVI-based signal to a DisplayPort-based signal with no impact on the video encoding or back-end recording solution. With a future-focused outlook, the ANSP can avoid needing unforeseen changes to multiple elements of the system that occur before the natural time for a replacement. |

|

Challenges in Recording & Streaming

With the advent of At-the-Glass hardware-based video recording, ANSPs can avoid problems associated with software-based recording. Historically software-based recording at the X server level suffered from issues associated with characteristics such as OS updates, the reliability of the presented data, and limited support for all connected systems resulting in ‘blank’ windows on playback. Hardware-based recording solutions address the issue of interoperability and related system updates by being passive to the system, however without consideration of the end-to-end solution, interoperability issues can still present challenges at the initial installation phase and during mid-life updates.

As a practical example, a typical ATM video-based recording system comprises of a local video encoder, a connected network, and centralized servers running dedicated software to capture the video data from the network. Typically, recording system providers will provide a ‘turnkey’ solution which comprises all required components, although in some instances an ANSP will choose a specific device for video encoding. Such video encoding devices may supply an open standard stream or a proprietary version and in each instance the recording system provider will need to conduct software integration. The data stream, device management, configuration, and status are all important elements that require software development by the recording system integrator, therefore any device change can be complex and costly.

A change in the ATC visual system, for example from DVI-D based video to DisplayPort based video, could have significant financial implications to the recording system. A DVI-D video encoding device would need to be exchanged for a DisplayPort supported device. A device which supports specific features, such as suitable frame rates, may not be available from the current video encoder vendor, forcing the ANSP to select an alternative manufacturer. In such an instance, the recording system integrator would likely look to charge for development of new features, leading to updates of the system software and a potential requirement to replace server components due to performance limitations. What began as a simple change from DVI-D to DisplayPort at the outset, becomes a greater burden on the ANSP requiring the replacement of a significant number of hardware and software components in the recording system.

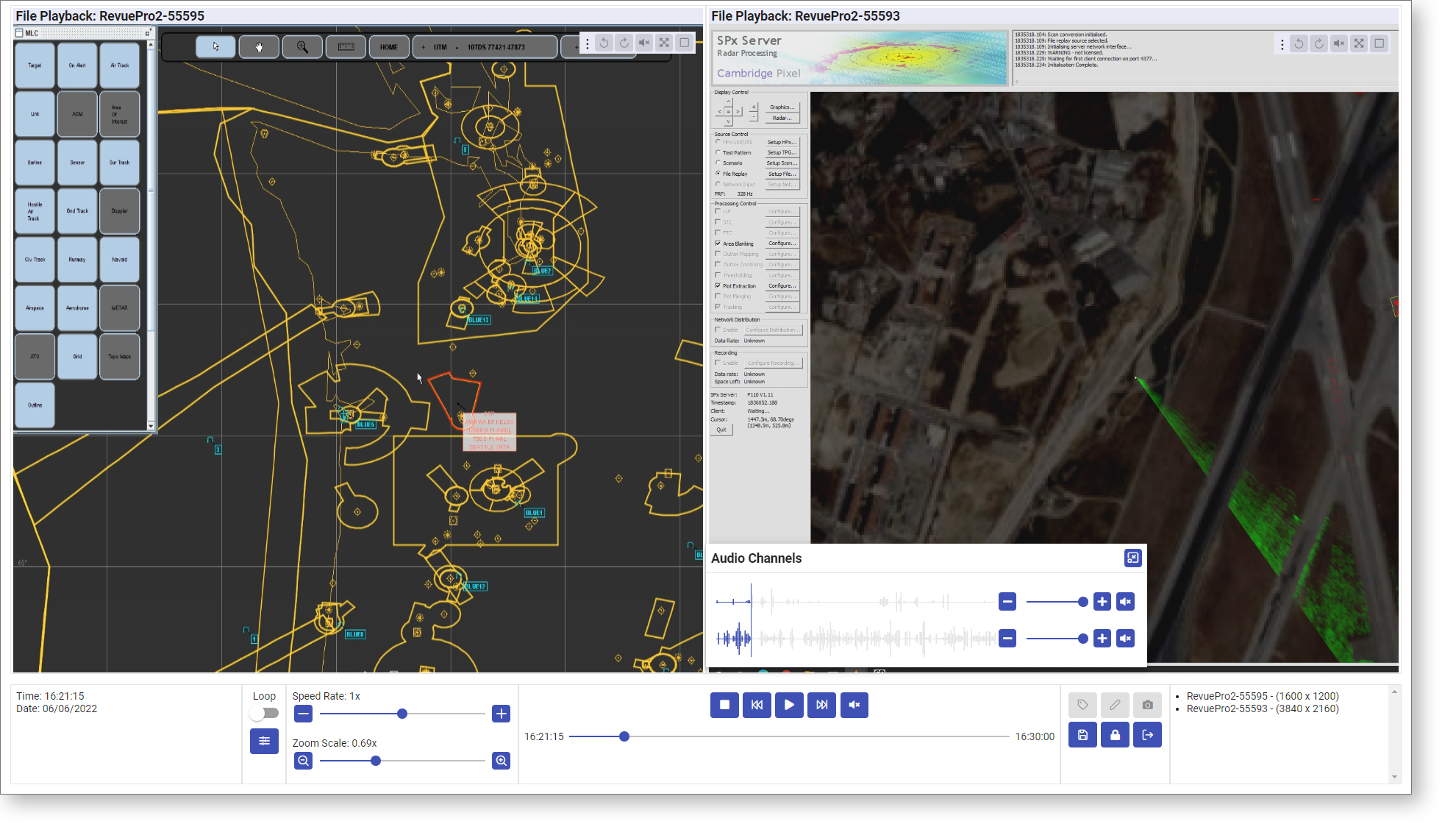

Playback of synchronized audio and video via EIZO’s Re/Vue encoding device and SafeGuard recording system.

By providing an end-to-end solution that includes its Re/Vue video encoders and SafeGuard recording system, EIZO eliminates initial compatibility issues in addition to ensuring minimal impact on other components in the system during mid-life updates. SafeGuard was designed to take advantage of the full Re/Vue feature set resulting in near real time live video streaming, ultra-responsive zoom and panning of multiple video sources during live view or playback and extensive support for monitoring and managing the attached encoder devices. In the above scenario, deployment of the Re/Vue encoders at the outset would allow the ANSP to only swap the cable connection from DVI-D to DisplayPort for the entire system to be migrated. This offers a potentially significant time, labor, and cost savings over that of a multi-vendor setup.

Challenges in Signal Management and Switching

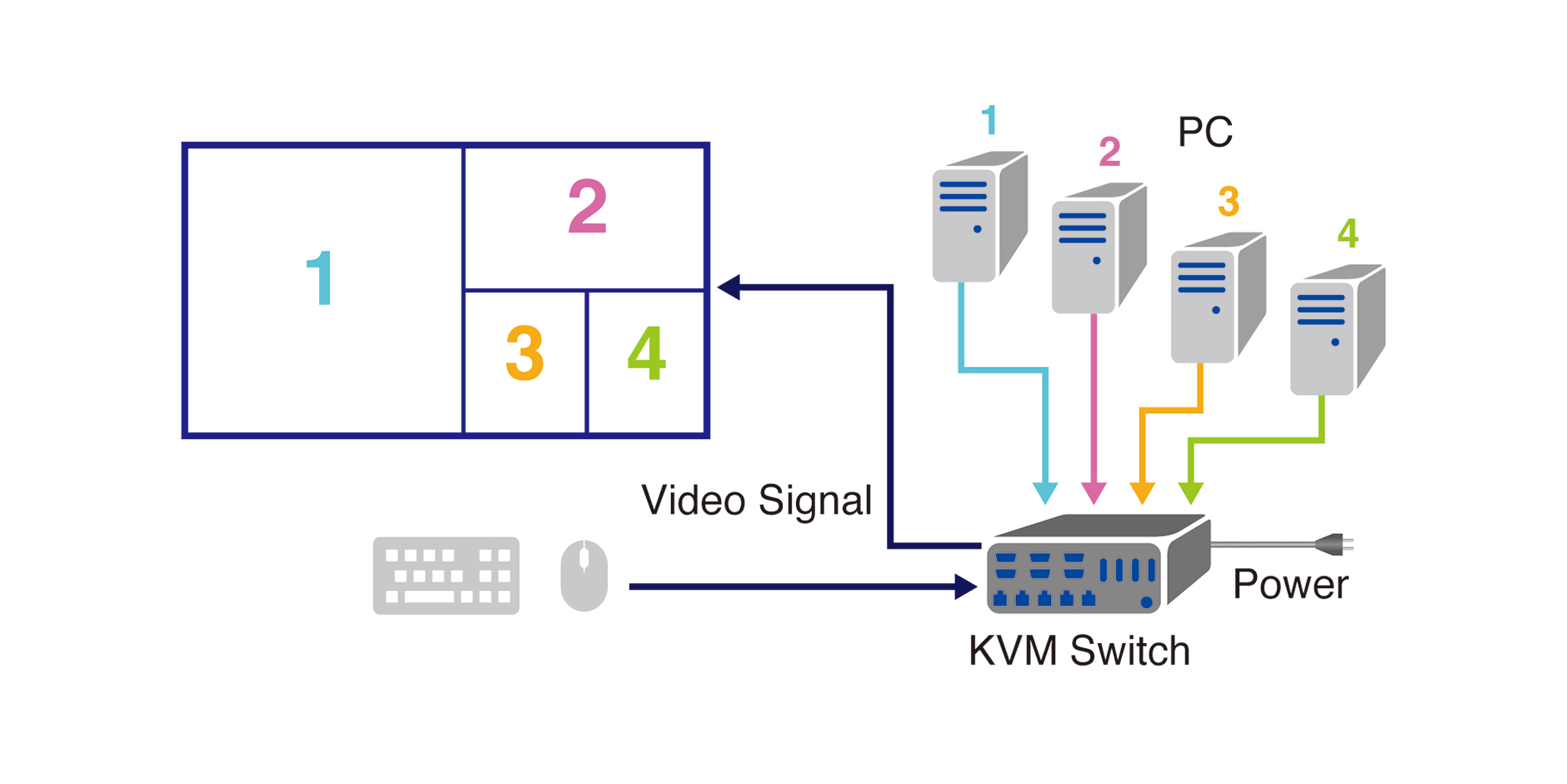

A typical ATM configuration consists of multiple workstations, monitors, and applications, between which the ATCO needs to frequently shift their view to track several variables including surveillance data, weather, flight strips, etc. In traditional configurations, a keyboard, video, mouse (KVM) switch has been an essential component to addressing the distribution and management of video signals and control across multiple workstations and monitors in ACCs, APPs, and control towers. A KVM switch is installed between the workstation (input) and monitor (output), to enable centralized control of multiple applications using a single keyboard and mouse. While this system addresses the initial concerns of signal management, there are also technical limitations and compatibility issues that increase points of failure throughout the system.

The KVM switch interfaces directly with the workstation and manages multiple signals between connected devices. It is often located away from the hardware to which it is connected, especially in installations with numerous controller positions and workstations. The signal transmission follows the path from workstation to KVM switch and then KVM switch to monitor and may travel a significant distance depending on the length of the cables needed to connect all devices. In this scenario, the longer the transmission path, the higher risk for signal degradation, which may cause latency or in some cases, complete loss of the signal.

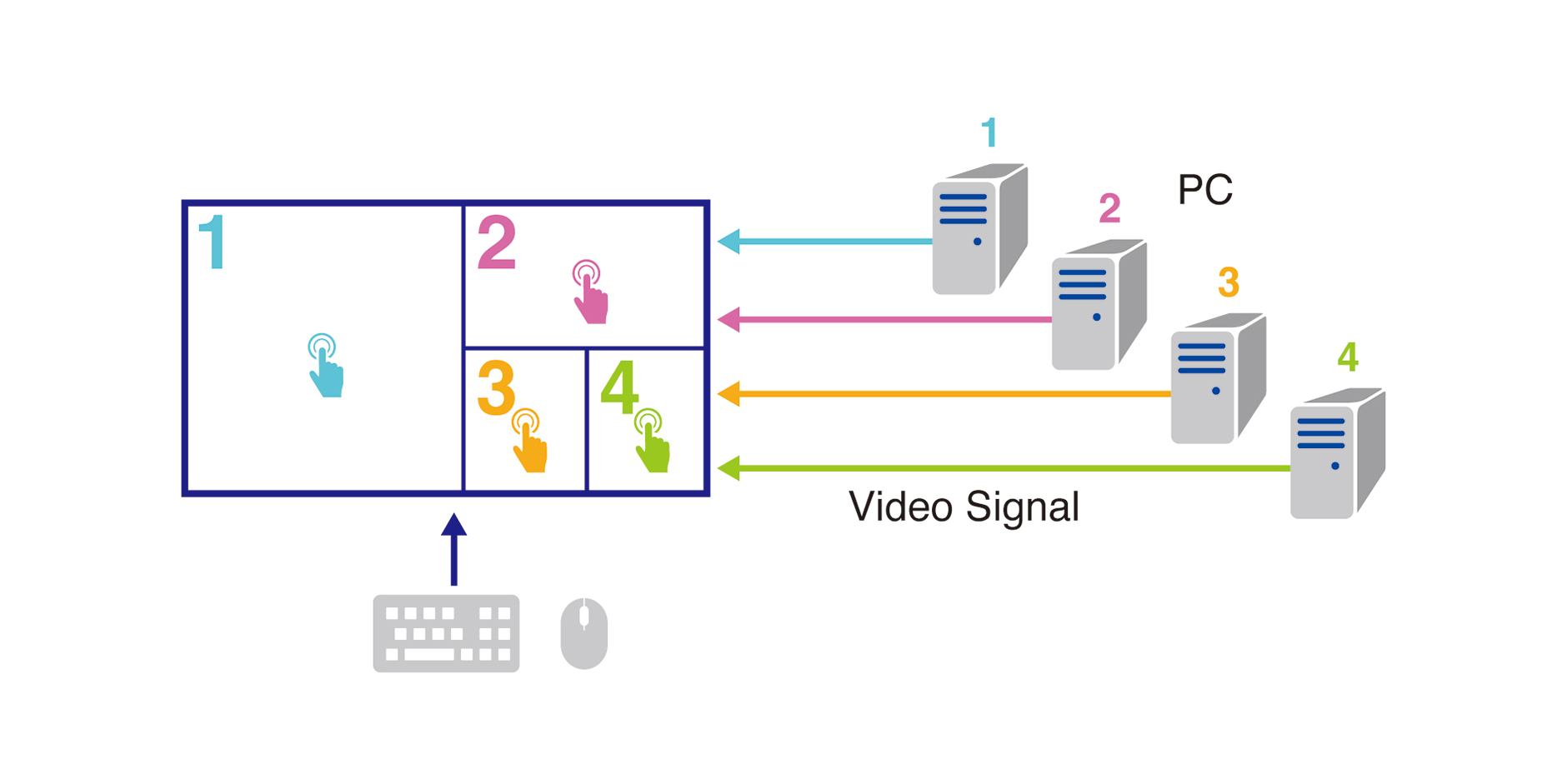

Traditional configuration using a KVM switch to manage video signals from four workstations on a single monitor.

Configuration using EIZO SwitchLink built-in switching technology to manage video signals from four workstations on a single monitor.

Loss of signal often occurs during the switching process itself. With a KVM switch, multiple input signals are compressed and output as a single signal. During this process, the signal received from the video source is disconnected and then reconnected before being output to the monitor. This process of detecting the monitor and outputting the video signal repeatedly can be a burden on the source workstation, as well as cause picture delay on the monitor.

EIZO has developed an answer with its SwitchLink integrated switching management solution. SwitchLink is integrated directly into Raptor monitors to enable seamless switching of keyboard, mouse, and dynamic touch input (a world first achievement) without the need for an external KVM switch. This not only saves the space that would otherwise be needed for the KVM switch hardware and cables, but also reduces the number of devices that need powering and simplifies signal management, resulting in fewer points of failure across the entire system. It also means the keyboard and mouse can be connected directly to the monitor without needing an extender.

As SwitchLink simply switches the DisplayPort signal within the monitor, signal transmissions are no longer compressed (disconnected and reconnected). This ensures reliable video transmission from the source workstation without loss of signal during the switching process. Furthermore, with SwitchLink, up to four video signal feeds can be connected to a single monitor, with the option to connect an additional two auxiliary monitors for configuration that operates up to six video sources via a single keyboard and mouse This further streamlines installation and simplifies the signal transmission path.

EIZO’s monitors with SwitchLink allow operators to operate up to 6 video sources using a single mouse and keyboard.

Learn more about SwitchLink in this article.

A Proven System

It is not uncommon for an ANSP to receive an integrated solution made up of multiple vendors’ products due to several motivating factors, one of which is related to initial cost of installation which may not take into consideration the long-term investment and costs of future upgrades or maintenance. Not taking proper steps to ensure a system will be free of critical errors or even minor idiosyncrasies prior to installation can cause significant delays in getting a new system operational and may lead to unforeseen costs needed to resolve compatibility issues during initial deployment or mid-life upgrades. ANSPs can mitigate these issues by engaging with expert manufacturers who can ensure interoperability during the design process, as well as carry out comprehensive testing before the solution is finalized.

EIZO has the widest range of products for ATC on the market with over 50 years of experience in visual solutions. EIZO’s ATC visual system encompasses monitors, video encoders, dedicated graphics boards, and an upgradeable recording solution, each of which is tailor-made to suit individual requirements and designed specifically for mission-critical air traffic control. In-house design, engineering, and manufacturing positions EIZO to advise on building a suitable architecture for an end-to-end ATC visual system, assist in future upgrade planning, and provide solutions that are designed and tested for interoperability from the outset. Furthermore, EIZO’s engineers can test hardware platforms and equipment ahead of deployment to mitigate potential risk and limit costly program delays. Choosing a proven, interoperable solution is key to ensuring the ATC visual system remains adaptable to technological advancements while ensuring reliability for long-term operation.

See the full range of products here.